SSZT214 December 2020 BQ75614-Q1 , BQ79600-Q1 , BQ79616-Q1 , BQ79656-Q1

Cell balancing is important in battery management systems for electric vehicles (EVs) because it helps extend vehicle driving ranges and ensure safe EV battery operation. Cell balancing is also required in order to correct imbalances in the battery itself. All batteries, including those found in EVs, experience unbalancing over time caused by mismatches during manufacturing processes or mismatches in operating conditions, leading to unequal aging between the cells.

A battery can only deliver a charge until its weakest cell has discharged completely, even though other cells may have plenty of charge left. Balancing the cells thus increases battery life by maximizing the capacity of the battery pack and ensuring that all of its energy is available, which in the case of an EV battery extends the driving range. Apart from maximizing battery capacity, cell balancing also ensures safe operation of the battery by preventing cell overcharge and overdischarge, both of which can lead to accelerated cell degradation and create potentially hazardous operating scenarios.

How cell balancing works

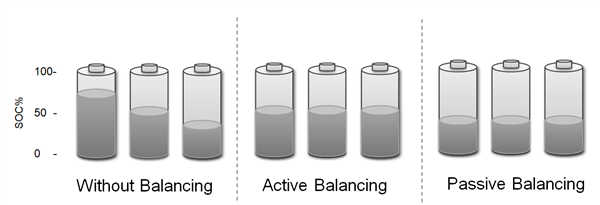

Cell capacity is often denoted by state of charge to explain the level of charge a battery has relative to its capacity. Figure 1 illustrates the differences in cell balancing types.

Figure 1 Battery state of charge in various balancing modes

Figure 1 Battery state of charge in various balancing modesPassive cell balancing in EV batteries

Improving EV battery safety with TI battery monitors and balancers

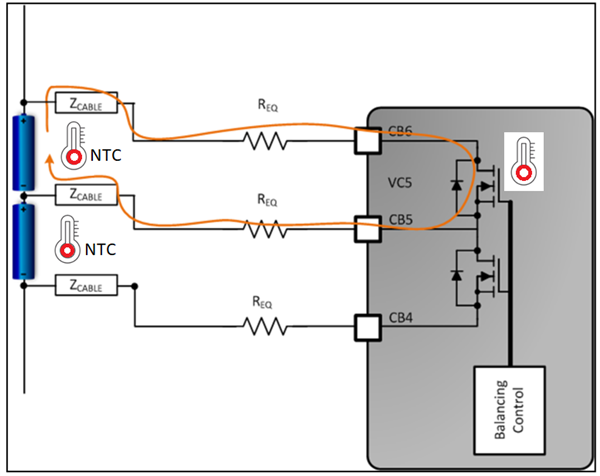

With thermistor monitoring, the BQ79616-Q1 automatically pauses balancing if the temperature exceeds a pause threshold. When the temperature falls below a recovery threshold, balancing resumes automatically. The BQ79616-Q1 pauses and resumes cell balancing in this case without any intervention from the MCU. Figure 2 shows temperature monitoring on the device and by the thermistors.

Figure 2 BQ79616-Q1 temperature monitoring locations on the PCB

Figure 2 BQ79616-Q1 temperature monitoring locations on the PCBThe cell-balancing pause state also freezes all balancing timers and settings, which do resume once the device is out of the pause state. To manage thermal increases caused by external balancing resistors, the BQ79616-Q1 can pause cell balancing on all channels if any of the active thermistors connected to general-purpose inputs/outputs detect a temperature greater than the set overtemperature cell-balancing threshold. Once overtemperature cell-balancing detection is triggered, the balancing on all enabled channels will resume once all active thermistors detect a temperature below the established recovery threshold.

Autonomous cell balancing helps maximize battery life, a key benefit for EV batteries. The addition of enhanced IC thermal management and fault indication to the MCU, as found in the BQ79616-Q1, enables quick and safe cell balancing in a cost-optimized manner for longer battery operation between chargers and a longer operational life for the EV battery.

Additional resources

- Watch the training video, “What is Cell Balancing?”

- Read the technical article, “How active and passive cell balancing works.”

- Read the Analog Design Journal article, “Cell balancing buys extra run time and battery life.”